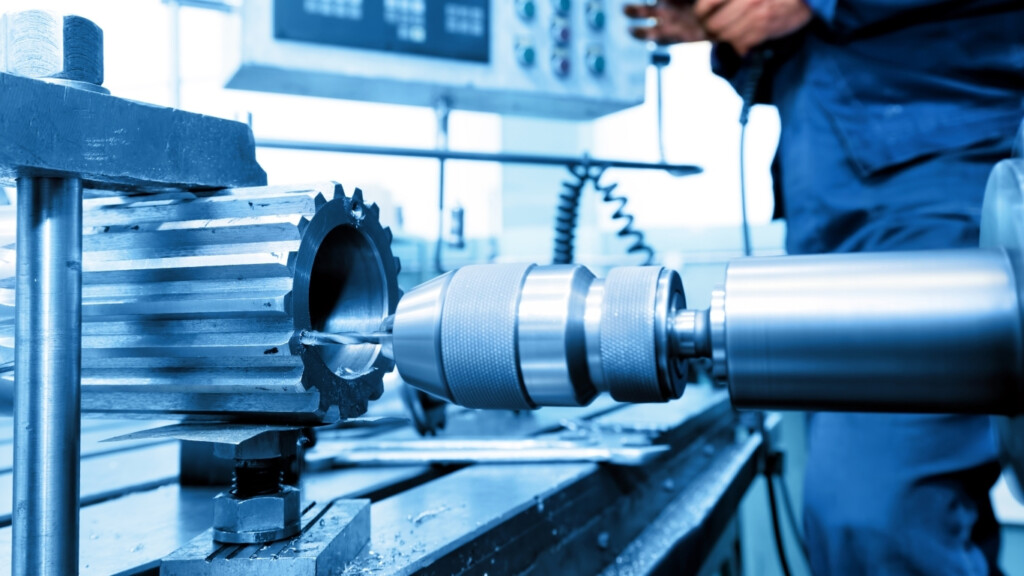

Choosing the Right Cutting Oil to Maximize Efficiency and Precision

In the world of high-precision metalworking, grinding plays a critical role in shaping materials with micrometric accuracy. Whether it’s for producing engine components, aerospace parts, or high-tolerance tooling, grinding is a process that demands not just the right equipment, but also the right cutting fluid. Among all types of metalworking coolants, synthetic coolants have emerged as the industry’s preferred choice for grinding applications.

Why? Because grinding is an operation that generates significant heat, demands immaculate surface finishes, and often deals with tough or hardened materials. And only synthetic coolants offer the combination of exceptional thermal control, chemical stability, and system cleanliness needed to meet these demands consistently.

What is Synthetic Cutting Oil?

Synthetic cutting oil, commonly referred to as synthetic coolant or synthetic cutting fluid, is a fully water-soluble, oil-free lubricant used in metalworking processes. Unlike mineral or semi-synthetic fluids, which contain petroleum-based oils, synthetic coolants are formulated with specialized chemical compounds that provide performance benefits without the drawbacks of oil content.

These fluids typically include:

- Corrosion inhibitors to protect machine parts and workpieces

- Lubricity agents to reduce friction between wheel and material

- Biocides and fungicides to resist microbial contamination

- Surfactants for better flushing of chips and abrasive debris

- Defoamers to maintain stable fluid circulation under pressure

Because they are oil-free, synthetic coolants leave no sticky residues, are clear in appearance, and offer superior cooling capabilities, making them ideal for high-speed, precision grinding operations.

Why Coolants Matter in Grinding

Grinding may appear simple, but it’s one of the most thermally intense operations in machining. As the abrasive wheel makes continuous contact with the workpiece, it generates friction that produces localized heat. This heat, if not managed properly, can cause:

- Surface burns and discoloration

- Micro-cracks or thermal expansion

- Reduced dimensional accuracy

- Premature wear of the grinding wheel

Coolants in grinding are not just optional, they are absolutely essential. Their role is to rapidly dissipate heat, flush away fine chips, reduce friction, and protect both the machine and workpiece from damage. The wrong coolant can result in surface defects, shorter tool life, and high operational costs. The right coolant, on the other hand, enhances surface finish, extends wheel life, and ensures long-term process consistency.

Why Synthetic Coolants are the Preferred Choice

Synthetic coolants offer several critical advantages that make them superior to traditional cutting fluids, especially in grinding environments.

1. Superior Cooling Performance

The water-based nature of synthetic coolants gives them exceptional thermal conductivity. They remove heat from the grinding zone faster than oil-based fluids, reducing the risk of burn marks or metallurgical damage and improving both dimensional stability and part quality.

2. Clean Running and Low Residue

Because synthetic fluids contain no oil, they leave behind virtually no residue on machines, tools, or parts. This results in:

- Cleaner grinding wheels with less glazing

- Easier inspection and measurement of finished components

- Lower maintenance requirements for equipment

3. Resistance to Bacterial and Fungal Contamination

Traditional coolants are often plagued by microbial growth, which leads to foul odors, degraded performance, and potential health hazards. Synthetic coolants are formulated with powerful biocides that:

- Resist bacterial degradation

- Prevent foul smells and fluid spoilage

- Reduce the need for frequent coolant replacement

4. Safety and Environmental Benefits

Synthetic coolants are non-toxic, non-flammable, and low in volatile compounds. They offer:

- A safer working environment for operators

- Lower skin and respiratory irritation

- Easier disposal and environmental compliance

5. Better Visibility and Process Control

Most synthetic coolants are clear or lightly tinted, giving operators better visibility into the grinding zone. This improves setup accuracy, allows quicker monitoring, and enhances overall process control, especially critical in tight-tolerance operations.

Key Factors to Consider When Choosing Synthetic Cutting Oil

Selecting the right synthetic coolant depends on several factors:

- Material compatibility: Some synthetics are designed specifically for ferrous metals, while others are suitable for aluminum and mixed-metal operations.

- Foam control: High-speed machines can cause excessive foaming if the coolant isn’t properly formulated.

- Water hardness: Hard water can reduce coolant stability; a compatible synthetic formulation is necessary.

- Required surface finish: Applications requiring ultra-fine finishes need coolants with high lubricity and EP (extreme pressure) additives.

Taking the time to match the coolant to your exact process can result in lower costs, higher productivity, and improved part quality.

Comparison with Mineral Oils and Semi-Synthetics

Here’s how synthetic coolants stack up against other commonly used cutting fluids:

Mineral oils provide excellent lubrication but poor cooling. They tend to leave heavy residues, generate smoke or mist, and promote bacterial growth, making them unsuitable for high-precision grinding.

Semi-synthetic fluids offer better cooling than mineral oils, but still carry many of the same issues. They contain some oil content, which leads to moderate residue build-up, reduced microbial stability, and more frequent sump maintenance.

Synthetic coolants, in contrast, provide:

- The best cooling performance

- Minimal system contamination

- Long sump life and excellent biological stability

- A clean, safe, and operator-friendly working environment

It’s this combination of benefits that makes them the top choice for modern grinding operations.

PAL SYNCO: PALCO’s Specialized Synthetic Coolants for Grinding

To meet the rigorous demands of today’s precision grinding industry, Paras Lubricants Limited has developed the PAL SYNCO series of synthetic coolants, designed specifically to enhance performance, reliability, and operator safety.

PAL SYNCO 100 & 200 – For Ferrous Metals

PAL SYNCO 100 and 200 are fully synthetic, mineral oil-free coolants developed for machining and grinding ferrous materials. These fluids are non-toxic, non-hazardous, and offer excellent mixing ratios for cost-effective use.

PAL SYNCO 100 is ideal for general grinding of steel and iron. It is fortified with corrosion inhibitors, bactericides, and fungicides, ensuring long fluid life and stable system performance.

PAL SYNCO 200 includes EP additives that improve surface finish, making it ideal for machining and grinding nickel-chrome steels and other non-alloyed ferrous metals. Both are recommended in clean circulating systems with dilution ratios of 4–8%.

Note: These coolants are not suitable for non-ferrous applications.

PAL SYNCO 300 & 400 – For Multi-Metal Applications

For grinding environments that involve multiple metals, including aluminum and ferrous alloys, PAL SYNCO 300 and 400 deliver superior versatility and cutting efficiency.

PAL SYNCO 300 is optimized for high-speed machining of ferrous and alloy steels, offering smooth finishes, excellent tramp oil rejection, and long sump life.

PAL SYNCO 400 extends compatibility to non-ferrous metals, including aluminum alloys, and is ideal for manufacturers dealing with diverse materials. These fluids provide:

- Excellent bio-stability

- Low foam during operation

- Enhanced tool life and consistent surface quality

All variants meet IS 11186-1985 standards, making them suitable for industries with high-quality benchmarks such as automotive, aerospace, defense, and general engineering.

In grinding applications, coolant selection is not a secondary concern, it is a central factor that can define the success or failure of your operations. The wrong fluid can result in surface burns, premature wheel wear, and costly maintenance. The right fluid, especially a high-quality synthetic coolant, can extend tool life, improve surface finish, and dramatically lower operational costs.

Synthetic coolants are the modern answer to the complex demands of precision grinding. With superior heat control, system cleanliness, biological resistance, and safety, they offer everything a manufacturing environment needs to stay competitive and compliant.

With the PAL SYNCO range from Paras Lubricants Limited, manufacturers now have access to synthetic cutting oils that are not just compatible with grinding, but specifically built for it. Whether your goal is cleaner operations, longer fluid life, or tighter tolerances, PAL SYNCO delivers performance where it matters most.