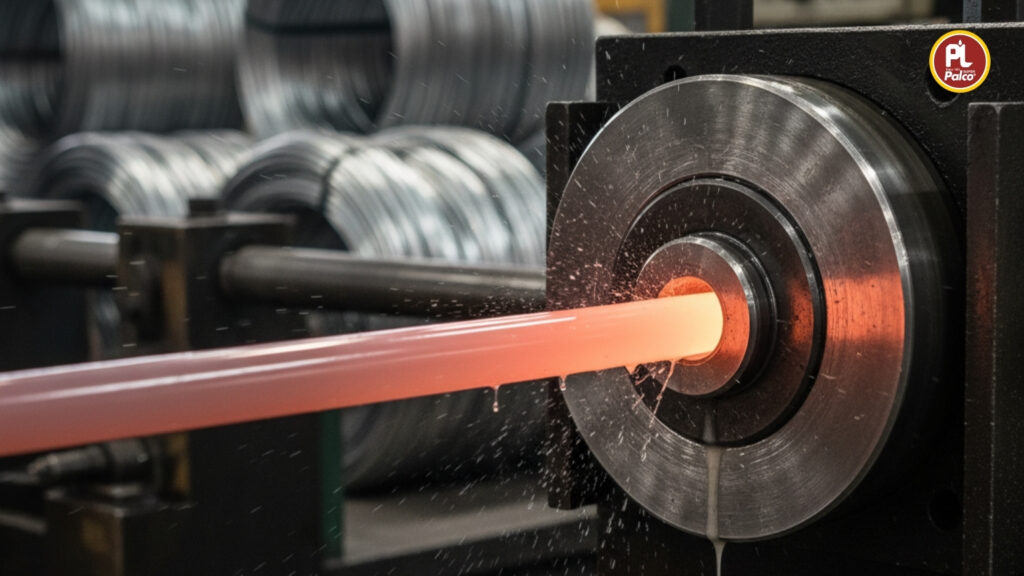

Metal forming and wire drawing are among the most essential industrial processes in manufacturing. From producing automotive parts to electrical wires and stainless-steel tubes, these operations demand extreme precision, high pressure, and reliable lubrication. The success of these processes depends greatly on the quality and performance of metal forming and wire drawing lubricants used.

These specialized oils and fluids ensure smooth metal flow, consistent shaping, and tool protection, all while maintaining the integrity and finish of the final product. Let’s understand what these lubricants are, their functions, and how high-performance solutions like PAL DRAW – ST2 and PAL DRAW – EP from Paras Lubricants Limited (PALCO) are redefining performance in metal forming operations.

What is Industrial Forming Oil?

Industrial forming oil is a high-performance lubricant used to reduce friction and wear between metal surfaces during processes like pressing, stamping, drawing, and extrusion. It acts as a protective layer, minimizing direct contact between the metal and the die, preventing scuffing, tearing, or breakage of the material.

These oils are generally mineral-based, semi-synthetic, or synthetic, formulated with additives that enhance cooling, anti-wear, and extreme-pressure (EP) properties. The right forming oil ensures precision in shaping, enhances die life, and delivers a superior surface finish.

Key Functions and Types of Forming Fluids

The role of a forming lubricant extends beyond friction reduction — it directly influences productivity, component accuracy, and overall process efficiency.

Key functions include:

- Reducing friction between metal and tooling surfaces

- Providing cooling under high-speed or high-load conditions

- Preventing metal-to-metal welding and die wear

- Ensuring smooth metal flow and improved surface finish

- Protecting against oxidation and corrosion

Types of Forming Fluids:

- Neat Oils: Used undiluted for heavy-duty applications such as cold forging and deep drawing, offering maximum film strength and EP protection.

- Soluble Oils: Emulsified with water for moderate applications that require both cooling and lubrication.

- Synthetic Fluids: Ideal for precision forming; they provide excellent oxidation resistance, thermal stability, and cleanliness.

- Dry Film Lubricants: Used in wire and tube drawing operations, forming a solid lubricating layer that minimizes friction and enhances tool life.

Each lubricant type is chosen based on the forming process, metal type, and operating conditions.

Why is Forming Oil Important?

In high-pressure forming or drawing operations, unlubricated metal surfaces can lead to severe wear, excessive heat, and even part failure. The use of forming oil is therefore critical to maintaining both efficiency and equipment longevity.

Forming oils help:

- Maintain uniform lubrication under varying loads

- Prevent surface scoring, tearing, and galling

- Extend die and tool life

- Improve dimensional accuracy and reduce rejections

- Enhance surface finish and appearance of final products

By improving tool life and minimizing downtime, forming oils directly contribute to cost savings and higher production efficiency.

Cold Forging Oils: Types, Importance & Application

Cold forging is the process of shaping metal at room temperature under immense pressure. Since there is no thermal softening, lubrication becomes vital to prevent metal pick-up, seizing, or cracking.

Types of Cold Forging Oils:

- EP-based Neat Oils – Provide strong film strength to handle heavy loads.

- Graphite and Soap-based Lubricants – Ideal for boundary lubrication of steel parts.

- Phosphate and Soap Coatings – Used as pretreatment for multi-stage cold forging.

Applications: Fasteners, shafts, bolts, nuts, bearings, and precision automotive parts.

A high-quality cold forging oil ensures metal deformation occurs smoothly, minimizes wear on dies, and guarantees accurate part geometry with minimal rejection.

PALCO’s Advanced Solutions: PAL DRAW – ST2 & PAL DRAW – EP

At Paras Lubricants Limited (PALCO), innovation meets performance. Our PAL DRAW Series is engineered to deliver exceptional lubrication and reliability in metal forming and wire drawing applications, ensuring consistent quality, reduced friction, and longer tool life.

PAL DRAW – ST2

A non-staining, high-performance mineral oil-based lubricant designed for high-speed and deep drawing operations.

- Offers excellent cooling ability and metal-wetting characteristics.

- Provides optimum film strength and lubricity even under extreme stress.

- Blended with anti-wear and EP additives to handle heavy loads.

- Maintains a stable lubricating film to prevent metal rupture, scoring, or breakage.

- Ideal for fine wire drawing and intricate metal forming operations.

PAL DRAW – EP

A chlorinated extreme-pressure (EP) lubricant, blended with fatty oils and free of active sulfur, making it suitable for severe drawing and cold rolling applications.

- Ensures a high-quality surface finish both internally and externally.

- Performs exceptionally under high pressure and temperature.

- Perfect for deep drawing and cold rolling of stainless-steel tubes.

- Not recommended for cuprous metals; slight staining may occur on high-nickel alloys.

Both formulations are engineered to withstand the extreme heat and stress of continuous operations, ensuring smoother metal flow, higher productivity, and longer equipment life.

Benefits of Using Metal Forming & Wire Drawing Lubricants

- Superior Tool Protection: Reduces wear, extending tool and die life.

- High Surface Finish: Prevents defects and ensures consistent quality.

- Enhanced Cooling: Controls temperature rise during high-speed operations.

- Energy Efficiency: Lowers power consumption by minimizing friction.

- Corrosion Resistance: Protects both workpiece and tooling surfaces.

- Operational Efficiency: Enables faster drawing speeds with reduced downtime.

Safety Measures in Using Forming Oils

To ensure safe and effective use:

- Always use personal protective equipment (PPE).

- Avoid prolonged skin contact; wash exposed areas thoroughly.

- Maintain proper ventilation in workspaces.

- Dispose of used oil responsibly, following environmental standards.

- Regularly monitor the lubricant’s condition for contamination or degradation.

Therefore, metal forming and wire drawing lubricants are more than just fluids, they are vital enablers of precision, performance, and protection in industrial manufacturing. The right lubricant enhances tool life, improves surface quality, and ensures smooth, trouble-free production.

With decades of expertise and ISO 9001:2015-certified manufacturing, Paras Lubricants Limited (PALCO) has developed advanced formulations like PAL DRAW – ST2 and PAL DRAW – EP to meet the growing demands of modern industries. These products not only ensure excellent lubrication and cooling but also embody PALCO’s commitment to engineering excellence and reliability.

Choose PALCO because every perfect draw begins with the right lubrication.